In industrial sectors, coolant pumps and rotary vane pumps are often used. Initially perceived as comparable entities, they possess distinct characteristics that render them suitable for distinct applications. This article explores the scenario of coolant pumps, emphasizing its benefits compared to rotary vane pumps.

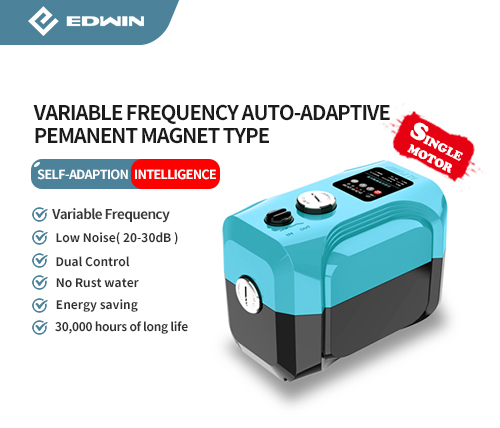

As implied by their title, coolant pumps utilise fluid as the primary conveyance mechanism. They find extensive usage in scenarios necessitating the circulation of water or other non-corrosive liquids. Renowned for their efficacy, dependability, and affordability, these pumps also embody environmental friendliness as water is a continually accessible and replenishable resource.

Conversely, rotary vane pumps employ oil as the mobile medium. More frequently employed in industries mandating the movement of viscous or caustic liquids, these pumps exhibit exceptional resilience against corrosion and can withstand elevated temperature and pressure conditions. Notwithstanding, they typically entail higher expenses and necessitate scheduled upkeep dues to the nature of the utilized oil.

English

English