Sale Horizontal Multistage Centrifugal Surface Well Pump in China

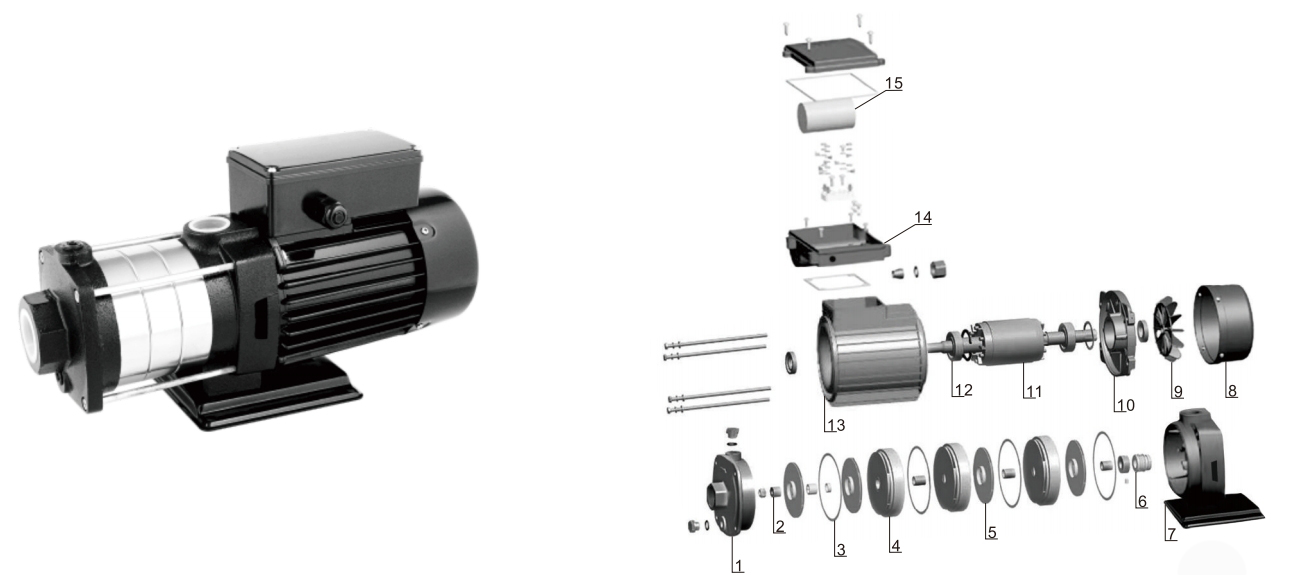

In the quest for sustainable industrial practices, the Horizontal Multistage Centrifugal Pump (HMCP) stands as a pivotal piece of equipment that requires careful consideration. These pumps are widely used in various sectors due to their ability to handle high pressures and large volumes of liquid. However, with the growing emphasis on energy conservation and environmental protection, the focus has shifted towards enhancing energy efficiency and reducing the environmental impact of Horizontal Multistage Centrifugal Pumps. This article will provide an in-depth analysis of the energy efficiency of HMCPs and discuss strategies to minimize their energy consumption and environmental footprint.

Energy Efficiency Analysis of Horizontal Multistage Centrifugal Pumps:

The energy efficiency of Horizontal Multistage Centrifugal Pumps is a critical factor in determining their overall performance and cost-effectiveness. By improving the efficiency of these pumps, industries can reduce their energy bills and contribute to global sustainability efforts. The efficiency of an HMCP can be influenced by several factors, including the design of the impeller, the materials used, and the operating conditions.

Strategies to Reduce Energy Consumption of Horizontal Multistage Centrifugal Pumps:

Engineers are constantly working on refining the design of Horizontal Multistage Centrifugal Pumps to reduce energy losses. This includes the use of computational fluid dynamics (CFD) to simulate and optimize the flow patterns within the pump, to more efficient operation.

Implementing variable speed drives in Horizontal Multistage Centrifugal Pumps allows for the adjustment of the pump's speed to match the system's demand. This not only saves energy but also extends the life of the pump by reducing wear and tear.

Regular maintenance of Horizontal Multistage Centrifugal Pumps is essential to ensure they operate at peak efficiency. This includes checking for wear, ensuring proper alignment, and replacing worn parts to maintain performance.

By analyzing the entire system in which Horizontal Multistage Centrifugal Pumps operate, inefficiencies can be identified and addressed. This may involve pipework modifications, changes in operating procedures, or even the replacement of older pumps with more efficient models.

Environmental Impact Assessment of Horizontal Multistage Centrifugal Pumps:

The environmental impact of Horizontal Multistage Centrifugal Pumps extends beyond energy consumption. Noise and vibration are two significant factors that can affect the surrounding environment and the health of workers.

Noise pollution from Horizontal Multistage Centrifugal Pumps can be mitigated through the use of sound enclosures, proper installation techniques, and the selection of pumps with lower noise levels.

Vibration can to structural damage and decreased pump life. To control vibration, it is essential to ensure that Horizontal Multistage Centrifugal Pumps are correctly installed and balanced. Anti-vibration mounts and regular monitoring can also help in reducing vibration levels.

The choice of materials for Horizontal Multistage Centrifugal Pumps can also have an environmental impact. Using materials that are durable, recyclable, and have a lower environmental footprint can contribute to sustainability.

Conducting a lifecycle analysis of Horizontal Multistage Centrifugal Pumps can help in understanding the overall environmental impact, from manufacturing to disposal. This information can guide the development of more sustainable pump designs and practices.

The Horizontal Multistage Centrifugal Pump is a cornerstone of industrial fluid handling, and its efficiency and environmental impact are of paramount importance. By focusing on design optimization, energy management, and environmental considerations, the industry can ensure that these pumps continue to serve their purpose while minimizing their energy consumption and environmental footprint. As technology advances, the potential for further improvements in the efficiency and sustainability of Horizontal Multistage Centrifugal Pumps is vast, promising a greener and more cost-effective future for fluid handling applications.

English

English