Improve machine efficiency and reduce energy consumption.

1. Reduce the internal leakage, external leakage and penetration of the machine, and improve the volumetric efficiency of the machine.

2. Reduce friction loss and improve the mechanical efficiency of the machine. For example, changing the double end face seal to a single end face seal, the unbalanced type to a balanced type, and the closed end of the double-supported bottom-reducing pump (the so-called chopper pump) can reduce the friction loss and improve the mechanical efficiency.

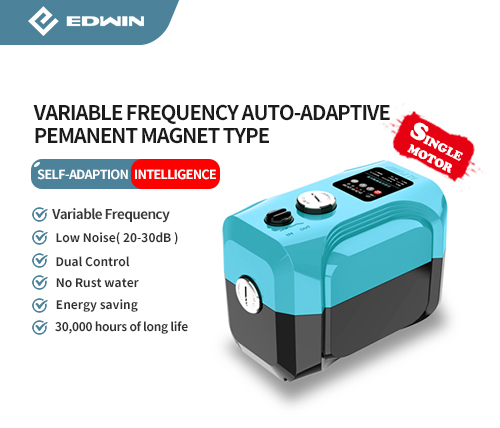

3. Change the sealing method to improve the efficiency of the machine or unit. For example, change the canned motor pump to a mechanical seal pump to improve the efficiency of the motor; use a magnetic drive pump to improve the efficiency of the machine.

4. Change the auxiliary system to reduce energy consumption and improve unit efficiency.

Save raw materials. For example, process fluid recovery, reduce or eliminate the loss of power steam and process fluid, and reduce oil sealing loss.

Improve machine reliability. For example, the leakage and life of the shaft seal determine the reliability of the shaft seal and the machine.

Safety and environmental protection.

English

English