Circulation pump provides cooling water to the condenser to cool the exhaust gas of the steam turbine and convert it into condensate water to establish a vacuum in the condenser. At the same time, it also provides cooling water for each auxiliary machine as a source of high and low pressure industrial water.

And then,how to choose the circulation pump to meet your needs ? Here are following a few suggestions :

And then,how to choose the circulation pump to meet your needs ? Here are following a few suggestions :

(1) The total flow of the circulating pump shall not be less than the total flow of the pipe network design. When there is a bypass pipe from the hot water boiler outlet to the inlet of the circulating water pump, the flow through the bypass pipe should be included.

(2) The flow head characteristic curve of the circulating pump should be relatively smooth near the working point of the pump, so that when the hydraulic conditions of the pipeline network change, the flow head of the circulating pump changes less. Under normal circumstances, the characteristic curve of the single stage water pump is relatively gentle, so the circulating water pump should choose the single stage water pump.

(3) The pressure and temperature resistance of the circulating water pump should be adapted to the design parameters of the heating system. Circulating water pumps are mostly installed on the return pipe of the heating pipe network. The circulating water pump is allowed to work at a temperature of not less than 60℃. If installed on the heating system supply pipe, you must use a high temperature resistant hot water circulation pump.

(4) The working point of the circulating pump should be within the effective working range of the pump.

(5) The determination of the number of circulating water pumps is related to the heating regulation mode adopted by the hot water heating system. The number of circulating water pumps shall not be less than 2 sets, and 1 set aside. When four or more pumps are operating in parallel, a backup pump cannot be set up. When using centralized quality control, the same type of pump should be used in parallel operation.

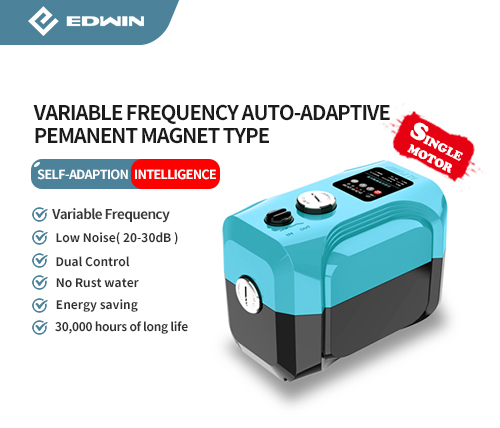

(6) Multiple heat sources are operated online or a single heat source heating system with central mass flow regulation, and the circulating water pump of the heat source should use a frequency control pump.

(7) When the qualitative regulation of the graded variable flow rate is adopted in the hot water heating system, the flow rate and head of each stage are different. In order to save energy, it is recommended to choose pumps with different flow rates and heads.

(8) For a hot water heating system with a hot water heating load, the flow rate of the pipe network in the non-heating period is much less than the flow rate of the pipe network during the heating period, so a circulating water pump with a special hot water load can be considered.

(9) When multiple pumps are running in parallel, the hydraulic characteristic curve of the pump and the heating pipe network should be drawn to determine the working point and select the pump.

English

English