Description :

The NTZ Series 2.2kW-11kW 380V Mass Flow Submersible Slurry Pump is the perfect solution for sludge treatment applications. With its professional and reliable design, this pump offers exceptional performance and convenience.

Featuring a 4-pole motor, this submersible slurry pump ensures an increased lifetime and greater convenience. The high chrome alloy impeller combined with an agitator allows for efficient pumping of heavy slurry, making it ideal for demanding applications.

The slim design of this pump, along with its top discharge, makes installation and maintenance a breeze. Additionally, the built-in thermal protection prevents motor overheating, ensuring safe and reliable operation.

Whether it's in the mining, construction, or wastewater treatment industry, this pump is designed to handle abrasive and corrosive materials with ease. Its high-quality materials and construction guarantee long-lasting performance in harsh environments.

With various power options available, you can choose the perfect pump to meet your specific sludge pumping requirements. Rest assured, this pump is reliable and durable, minimizing downtime and maximizing productivity.

As a testament to its quality, the NTZ Series 2.2kW-11kW 380V Mass Flow Submersible Slurry Pump is backed by a comprehensive warranty and excellent customer support. Invest in this pump today and experience the difference it can make in your sludge treatment operations.

Application :

●Civil engineering

●Mines,quarries,coal ore & slurries

●Sewage treatment plants

●General pumping purposes

●Pumping fluid:sludge ,liquids-containing,mud and bentonite

Special features on request :

●Other voltages and the length of cable is optional

Specification :

●Capacity : up to 246m3/h

●Head : up to 22.5 meters

●Discharge : 80mm(3") to 150mm(6")

●Power : 2.2kW (3HP) to 11kW (15HP)

●Power suppy : three phase 380V+10%

●Insulation class : F

●Protection class : IP68

●Cable length : 8m

●Water temperature : up to 40°C

●Max. water depth : 20m

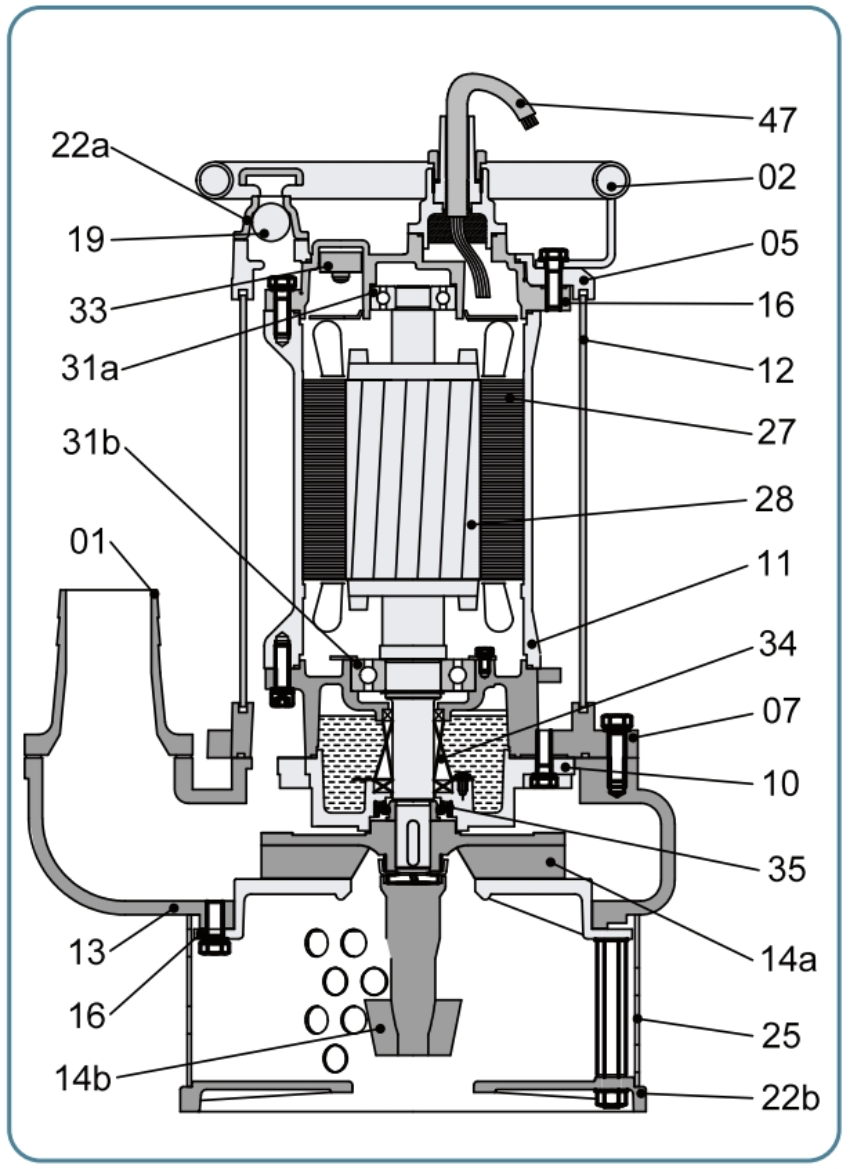

Materials of construction :

|

Materials Table

|

|

NO.

|

Name

|

Material

|

|

01

|

Hose coupling

|

Cast iron

|

|

02

|

Handle

|

Rubber & steel

|

|

05

|

Upper cover

|

Cast iron

|

|

06

|

Upper support

|

Cast iron

|

|

07

|

Bearing house

|

Cast iron

|

|

10

|

Seal house

|

Cast iron

|

|

11

|

Motor body

|

Cast iron

|

|

12

|

Outer casing

|

Steel

|

|

13

|

Pump body

|

Cast iron

|

|

14a

|

Impeller

|

High chrome alloy

|

|

14b

|

Agitator

|

High chrome alloy

|

|

16

|

Intel Plate

|

Ductile iron

|

|

19

|

Check value

|

NBR

|

|

22a

|

Valve seat

|

Cast iron

|

|

22b

|

Seat assembly

|

Cast iron

|

|

25

|

Strainer

|

Steel

|

|

27

|

Stator

|

|

|

28

|

Rotor

|

Shaft : AISI420SS

|

|

31a

|

Bearing

|

Ball bearing

|

|

31b

|

Bearing

|

Ball bearing

|

|

34

|

Mechanical seal

|

Sic-Sic / Sic-Sic

|

|

35

|

Oil seal

|

|

|

47

|

Cable

|

|

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View